Trending Products China Korean Technology Sintered stone cutting machine with Excellent Performance

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Staff and assure you our best company and product for Trending Products China Korean Technology Sintered stone cutting machine with Excellent Performance, We persistently establish our company spirit “quality lives the company, credit assures cooperation and retain the motto in our minds: clients initially.

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Staff and assure you our best company and product for Sintered plate cutting machine, Sintered Stone Cutting Machine, Our company upholds the spirit of “innovation, harmony, team work and sharing, trails, pragmatic progress”. Give us a chance and we’ll prove our capability. With your kind help, we believe that we can create a bright future with you together.

智能,高速,稳定性好,安全方便,节省人力,提高效率

型号可以定制:

智能高速玻璃切割线由自动玻璃装载台,自动玻璃切割机和自动空气破碎台组成。它是一种具有自动加载,自动排版和切割功能的自动玻璃切割系统。智能切割线具有稳定性好,安全方便,节省人力,提高效率等优点,是玻璃深加工的首选设备。加工企业。

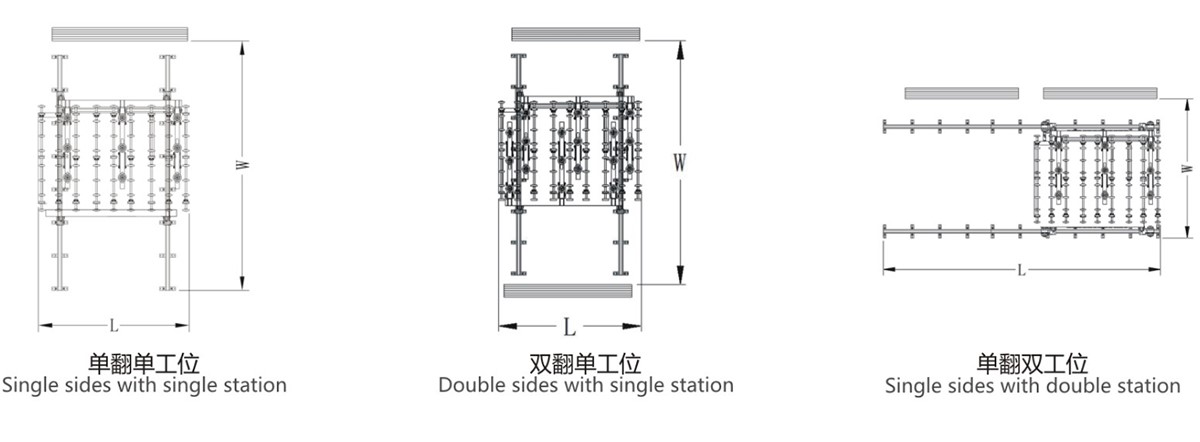

自动玻璃装载平台是一种安全,高效,快速的手动玻璃切割设备的替代品,根据装载平台的不同,通常分为:单转单工位,单转双工位,双转单工位,双转双工位。无论哪种工作原理相同,客户都可以根据加工厂的生产和地点以及其他因素做出合适的选择。

基本工作原理:

It is mainly used for automatic glass loading.Put glass in the specified location, after the loading signal is given, The big arm is flipped up by 95°-100° through the overturning mechanism, the machine began to walk forward, while the sensors on the forearm when in contact with the glass, the machine stop walking,the sucker absorbs the glass through the vacuum system,The forearm lifts the glass back and up by about 20mm for separating the glass, delay separating, again on the back rise above 80 mm, after walking motor back arm fall at the same time, after the big arm in place, under the glass sucker began to blow, forearm falling glass land on conveying wheel at this moment, the last, through the delivery send glass to cut on the stage.Sintered stone cutting machine

Features: Laser automatic positioning, graphic scanning, automatic labeling,straight line & special-shaped cutting, high cutting precision, fast cutting speed, long service life, no consumables

Fully independent research and development, design, production, can be customized according to the special needs of users.

Adopt HD industrial display screen, aluminum alloy profile shell, explosion-proof, dustproof, super long service life. Ultra wide viewing Angle and ultra high display brightness.

Specially developed 6mm thick 6061 high strength industrial aluminum beam to remove internal stress, to ensure the service life and load-bearing capacity of aluminum beam, large milling machine processing installation surface, to ensure the perpendicularity and straightness of the installation surface, improve the accuracy

Adopt high strength national standard carbon steel, robot full welding process, the whole body heat treatment, stress removal aging treatment, to ensure the body stability and flatness

Dual drive servo motor with high horsepower、the machine ensures high precision while cutting at high speed、adopt Italian special cutting head for rock slab

It can be applied to the following areas:

Building decoration, craft home decoration, cabinet furniture

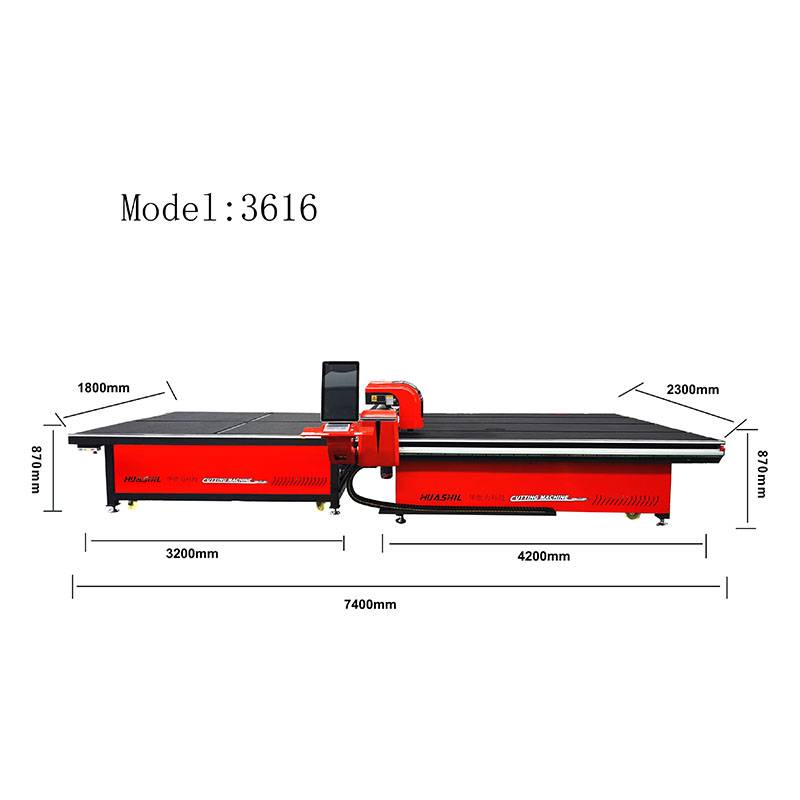

Technical Parameters Machine parameters Dimensions Length * width * height:7400mm*2300mm*1420mm

Weight 2500kg

Table height 880±30mm(Adjustable feet)

Power requirements 380V,50Hz

Installed power 10.5kW(Use power3KW)

Compressed air 0.6Mpa

Processing parameters Cut glass size MAX. 3600*1600mm

Cut thickness 3~15mm

Head beam speed X axis 0 ~ 200m / min (can be set)

Head speed Y axis 0 ~ 200m / min (can be set)

Cutting acceleration ≥6m/s²

Cutting knife seat Cutting head can rotate 360 degrees (precise cutting of straight lines and special shapes)

Cutting accuracy ≤±0.2mm/m(Based on the size of the cutting line before the sintered stone breaking)