2021 High quality Glass Edge Processing Machine - High Precision Glass Double Edger Machine – Huashili

2021 High quality Glass Edge Processing Machine - High Precision Glass Double Edger Machine – Huashili Detail:

Description

The High precision glass double edger machine is suitable for grinding flat glass with double straight sides.

Rough grinding, fine grinding, polishing safety angle (installed safety chamfering wheel) once completed.

Grinding head sliding with double straight rolling guide, double ball screw drive to reach a stable moving speed, eliminate mobile clearance, reduce resistance and friction, to ensure repeat positioning.

PLC control system set the processing parameters by the interface to complete the processing.

The use of automatic compensation polishing brake mechanism to ensure the surface finish after grinding. Width opening and closing and crawler drive using high-power inverter motor. Speed control, constant power, constant twist rejection output, stable and reliable.

Features

a stable and solid structure

accurate and smooth rotation system

high configuration of the control system

large size of the processing capacity

Application

The High precision glass double edger machine can be applied to the following areas:

Craft glass

Small pieces of glass crafts edge grinding

Home decorated glass

Home decorated glass , home glass edging

Architectural decoration

Building decoration, mirror、 Ceramic tile、 composite ceramic tile、 artificial stone、 microcrystalline stone edge grinding

Deep processing of glass and other industries

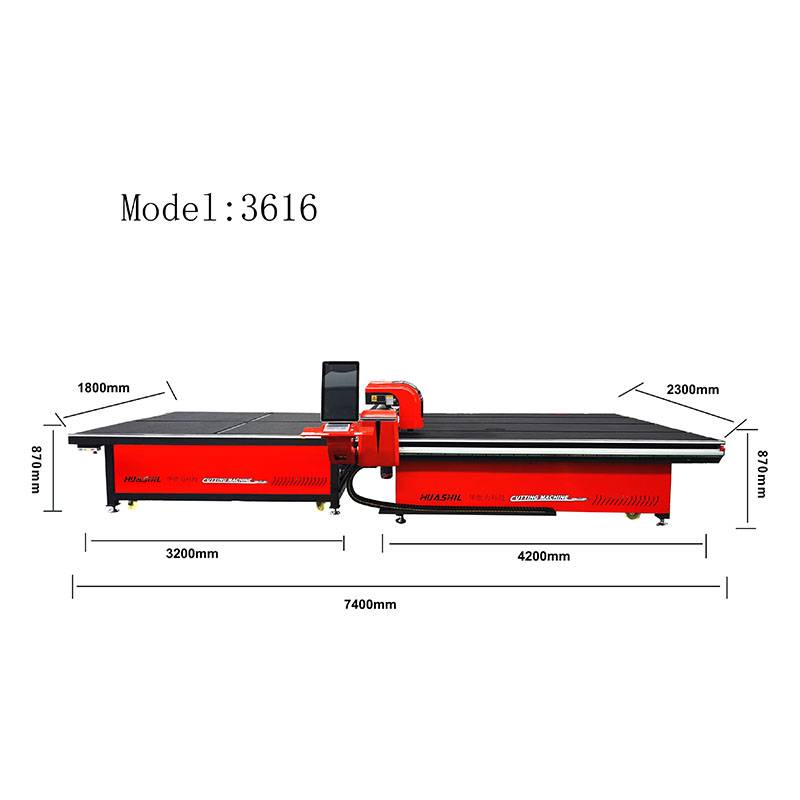

Parameter

|

Dimension |

Min processing size |

Max processing size |

Glass processing thickness |

Glass transfer speed |

Power |

Weight |

| 2500*2100*1700mm | 100*100cm | 1100*1100mm | 2-10mm |

0-12m/min |

11kw |

4000kg |

| Voltage | 380V 50HZ |

| Power | 11kw |

| Dimension(L*W*H) | 2500*2100*1700mm |

| Weight | 4000kg |

| Warranty | 1 Year, One Year |

| After-sales Service Provided | Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Overseas third-party support available |

| Key Selling Points | Long Service Life |

| Grinding head number | 4(customization) |

| Conveying speed | 0-12mm/min |

| Processing thickness | 2-10mm |

| Minimum processing size | 10 * 10 cm |

| Maximum processing size | 1100 * 1100mm |

| Name | High precision glass double edger machine |

Advantage

Safety, durability, high efficiency, professional design, small size and large energy

High accuracy and high speed

Customized for you

Can provide technical solutions according to customer requirements

Linear guide ,Roller screw

Lean manufacturing is just for the better

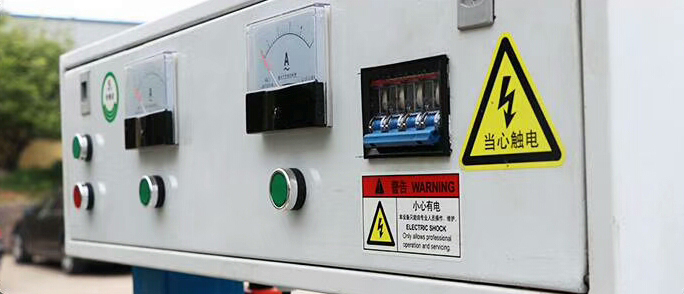

PLC control

automatic monitoring

Fault Alarm

Servo drive

Thickness Adjusting

Equipped with four 30RV reducer synchronous adjustment, with digital display, the thickness of arbitrary adjustment

Servo motor

Servo motor drive, one side can be used independently, two side use synchronization is more stable and accurate

Adjustable dovetail

Adjustable dovetail Front, back, left, right precision adjustment

Both- way dovetail adjustment, before and after precision adjustment

Brand motor

The main power supply adopts Delixi brand, and the auxiliary power supply adopts Chint electric, which is durable and reliable

Product detail pictures:

Related Product Guide:

Our commission is to serve our users and clients with best quality and competitive portable digital products for 2021 High quality Glass Edge Processing Machine - High Precision Glass Double Edger Machine – Huashili , The product will supply to all over the world, such as: Durban, New Zealand, Lahore, We have 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export products to other countries. We expect to cooperate with you to develop a larger market.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.